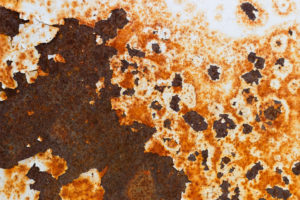

The core of our business is related to corrosion. While the term is most commonly associated with metals corrosion has been defined as the deterioration of a material or its properties due to a reaction of that material with its chemical environment. Corrosion is the result of natural processes that seek to return materials to their original state, such as minerals or elemental carbon. Nearly any material, if exposed to the elements long enough, will corrode.

Corrosion is a major cost for our economy and quality of life – a 2001 study estimated the cost of corrosion in the United States was $276 billion dollars per year (3.2 percent of the U.S. gross domestic product). This estimate does not include indirect costs such as those resulting from inconvenience to the user after a corrosion failure. Clearly the impacts of corrosion on society are significant. Elzly provides expertise in a variety of technology areas including protective coatings and linings, cathodic protection and materials selection. The following paragraphs provide an overview of the technology areas in which we work.

Corrosion Engineering

New and innovative approaches to corrosion control have been under development throughout the modern era. However, corrosion control requires consideration of cost, effectiveness and need. As a simple example, consider the choice between stainless steel versus carbon steel screws. Steel is probably adequate for hanging pictures in your house even though stainless steel would not exhibit rust staining for a longer period of time.

This simple example becomes considerably more complex when extensive infrastructure is being designed or maintained. An engineered approach to corrosion control requires awareness of the corrosion costs. This can be accomplished on existing structures through corrosion surveys of an owner’s assets and/or analysis of condition-based maintenance data. For new structures, design practices should consider elements which can effect improved corrosion management. Elzly has worked to develop advanced life prediction and performance assessment methods which can help in either of these areas.

Once the costs are understood, technologies can be identified which have the potential to affect savings. Of course, the people who design and operate equipment and facilities can have a great effect on the impact of corrosion.

Protective Coatings

Of the technologies used to control corrosion, protective coatings are by far the most significant. Approximately 90% of all expenditures associated with corrosion control are related to protective coatings. But, a properly selected and applied coating system will reduce the rate of corrosion and, thus future costs associated with corrosion control and mitigation.

Of the technologies used to control corrosion, protective coatings are by far the most significant. Approximately 90% of all expenditures associated with corrosion control are related to protective coatings. But, a properly selected and applied coating system will reduce the rate of corrosion and, thus future costs associated with corrosion control and mitigation.

Protective coatings provide corrosion protection by one or a combination of three methods – by acting as a barrier, an inhibitor, and/or a sacrificial anode. Nearly all coatings provide some level of barrier protection. Barrier coatings reduce environmental access to the substrate. This reduces or eliminates corrosion by isolating the electrolyte from the metal surface. Inhibitive coatings contain pigments that react with moisture vapor absorbed by the coating. The resulting ions react with the steel surface, passivating it, thus preventing corrosion. Sacrificial coatings are rich in a sacrificial metal (usually zinc). The zinc acts as the sacrificial anode that corrodes instead of the steel structure.

Cathodic Protection

Cathodic protection is a technique or system used to reduce or eliminate the corrosion of a metal by supplying current to the structure from a dc-power supply or attachment of sacrificial anodes such as zinc, magnesium, or aluminum. The application of the external current serves to reduce the natural electrochemical tendency for the base material to corrode.

Cathodic protection is a technique or system used to reduce or eliminate the corrosion of a metal by supplying current to the structure from a dc-power supply or attachment of sacrificial anodes such as zinc, magnesium, or aluminum. The application of the external current serves to reduce the natural electrochemical tendency for the base material to corrode.

Materials Selection

Designers today have a larger range of material selection options than at any other time. Elzly engineering staff provides assistance to allow designers to best understand how metallic and non-metallic materials will function within the intended service. Guidance is also provided concerning cost-effectiveness, material life-cycle, and material regulatory considerations

Environmentally Sustainable Processes

Environmental and safety / occupational health regulations impact material preservation processes. 21st-century industries focus on developing sustainable processes. Elzly provides analyses to help align preservation practices with environmental and safety regulations.